Client: Bikaji Foods, Bikaner

- Project cost: 140 Cr. (Appx)

- Total built up area: 5.5 lakh Sq. ft.

- Project Duration: 2 Years

- Project highlights:

- 16 snacks lines (Phase I) with throughput planned for 480 TPD

- Plant designed to meet US FDA and Global food safety – BRC Standards

- Scope involved in equipment selection, process engineering, layouting, utility designing

- 1 Cr.Kcal thermic fluid heaters, 4 MvA installed power,

100% DG backup - HVAC – 1000 TR of Air conditioning with RH control in packaging areas, 2 stage cooling (over 2 L CFM) systems rest of the areas.

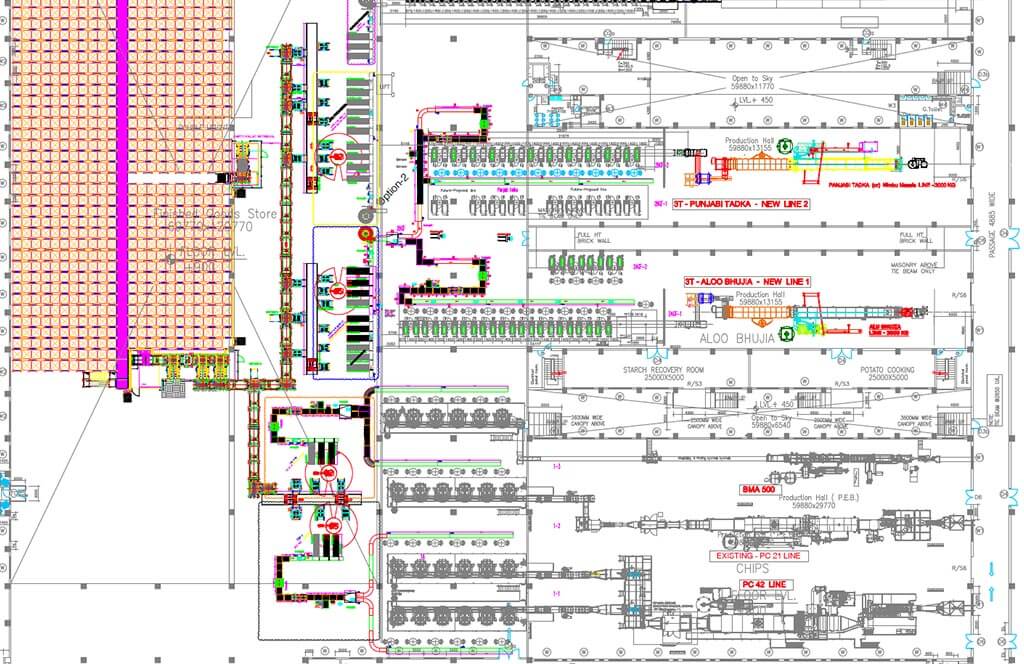

Client: Haldirams, Nagpur

- Project cost: 80 Cr. (Appx)

- Total built up area: 3.5 lakh Sq. ft.

- Project Duration: 1.5 Years

- Project highlights:

- Multiple lines with throughput planned for 300+ TPD

- Plant designed to meet Global food safety standards

- Involved in process automation, utility designing and commissioning

- 2.5 Cr. Kcal thermic fluid heaters

- HVAC using waste heat in VAM chillers for Air conditioning with RH control in packaging areas

- Packaging automation with robotic palletization and ASAS for @8000 pallets locations

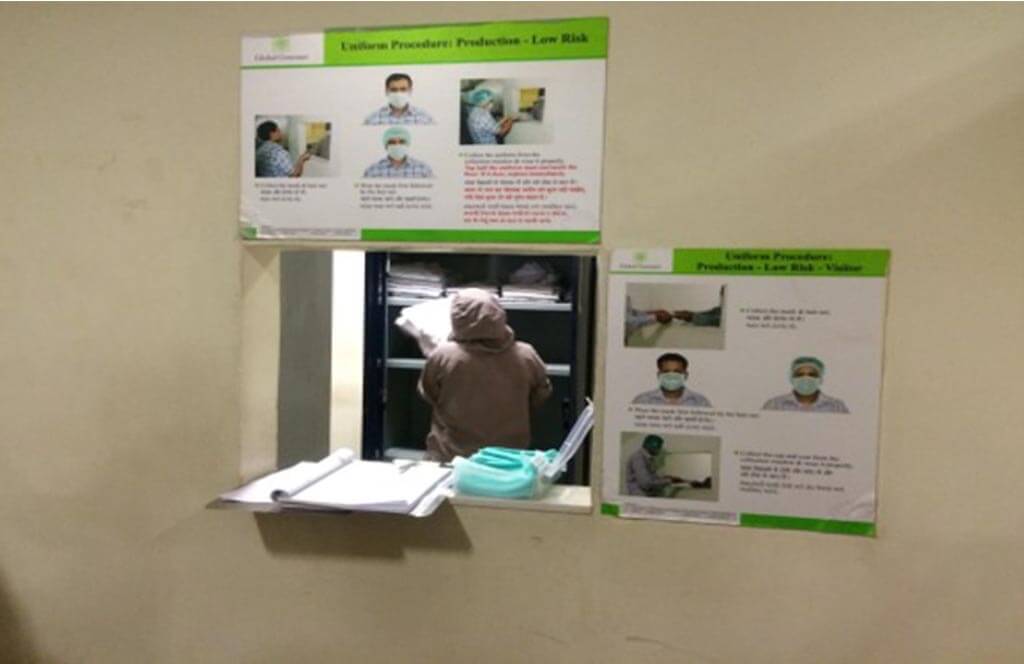

Client: Global Gourmet

- Global benchmark in Global Frozen food business

- Designing of the factory as per international standards / legislations, customer requirements and COPs – equipment selection, lay outing

- Equipped with state-of-the-art infrastructure and latest processing technology

- Got the US FDA approval, EU, BRC Certification (A) with-in 3 months of commissioning. Currently certified for A+

- Got approval from the TESCO-UK, – one of the first Indian company to get so for frozen in 3P – currently Tesco Blue Certified

- Got approval from other customers like Trader Joes, Pillsbury, Brakes Brothers.

Client: Everest Spices, Mumbai

- Project cost: 80 Cr. (Appx)

- Total built up area: 1.2 lakh Sq. ft.

- Project Duration: 2.0 Years

- Project highlights:

- Production capacity – 100 MT/day of blended Spices

- Involved in technology selection, plant design, utility designing

- State-of-the-art infrastructure – Grinding, blending and automatic recipe management

- Facility made to comply with international standards & productivity

- High speed packaging lines, cryogenic grinding of high quality spices

Client: Everest Spices, Umergaon, Gujarat

- Project cost: 120 Cr. (Appx)

- Total built up area: 2.5 lakh Sq. ft.

- Project Duration: 1.5 Years

- Project highlights:

- Infrastructure designed for 400 MT/day blended Spices

- Design objective is major reduction in man power

- Involved in process engineering, technology selection, utility engineering, project management

- High throughput grinding lines with recipe automation, testing lab

- Automatic storage & retrieval systems (ASRS) for raw materials for 2000 pallet & finished goods, packaging materials for 9000 pallet locations