Introduction:

Lean management is a systematic approach towards reducing the lags of manufacturing at every production process level. Lean management is implemented in various critical areas of food and beverage manufacturing units to eliminate problems like insufficient raw material, ineffective packaging, lengthy production methods, lack of uniformity, and, most notably, getting rid of the waste.

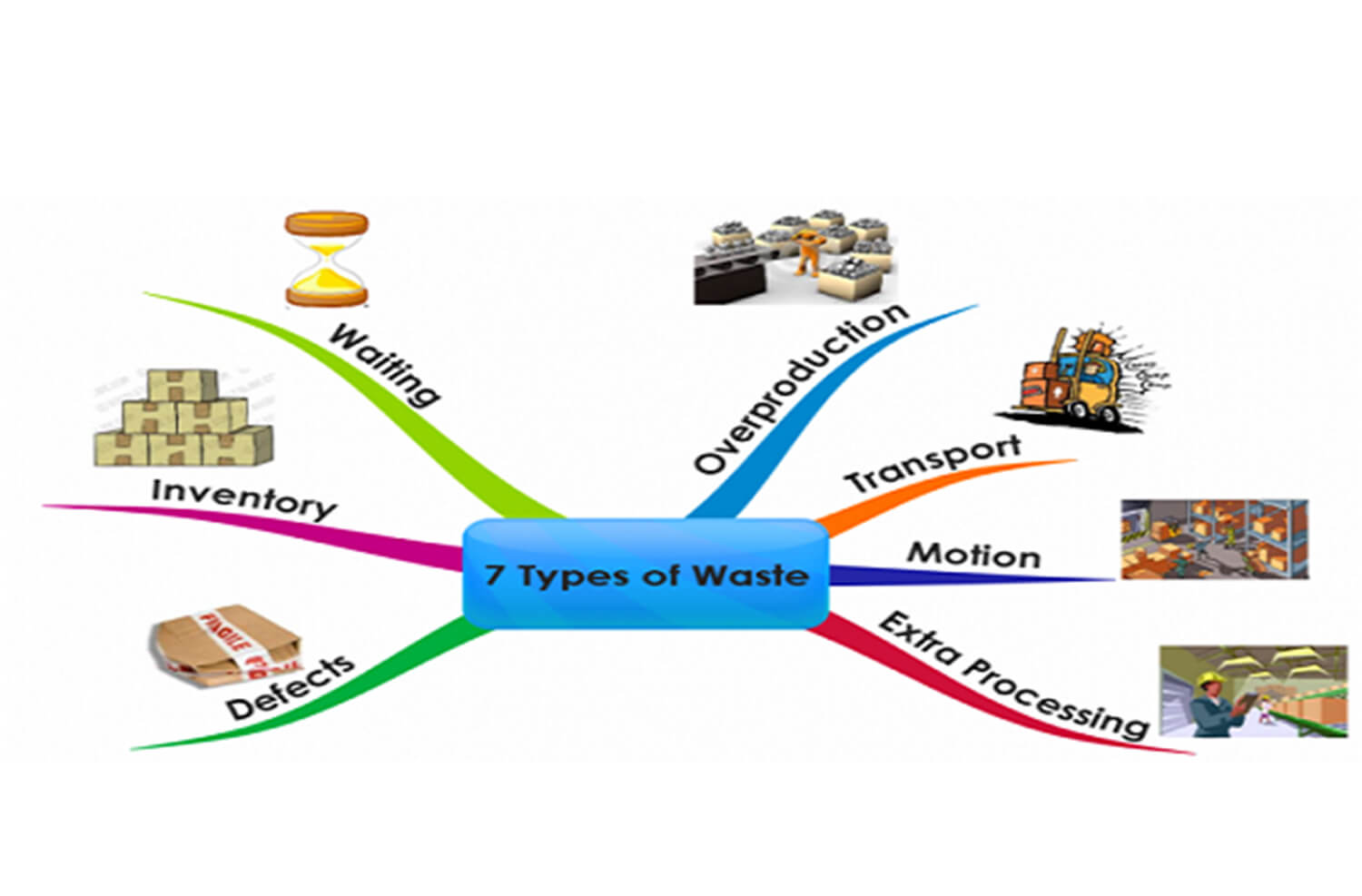

Seven Wastes :

The production line of food starts from the farm where raw materials are grown and ends at the supermarket where readymade units are available for sale. In between these two points, the food material goes through a lot of stages and levels. This complicated web of manufacturing creates “waste” at every step of the way. The eight most prominent wastes that hinder Lean Management are as under:

The production line of food starts from the farm where raw materials are grown and ends at the supermarket where readymade units are available for sale. In between these two points, the food material goes through a lot of stages and levels. This complicated web of manufacturing creates “waste” at every step of the way. The eight most prominent wastes that hinder Lean Management are as under:

1. Production flaws:

Production flaws result in unusable end products. These flaws are identified as “defects” by the lean management system. Production flaws take the most significant chunk of wastes because it not only reduces the profit quotient to zero but also increases the pressure of unbalanced cost incurred on the system. Lean management identifies the following reasons for defects:

Reasons:

- Unsynchronized production methods.

- Lack of innovation and improvement.

- Inefficient Standard operating procedures.

- Poorly implemented regulations.

2. Labor utility:

The workforce of a manufacturing unit is like a lifeline. Just like blood cells circulate the entire body to nourish, repair, and upkeep the human body, the factory workers keep the production line going. However, the human factor of corruption is responsible for creating a labour waste called “non-utility of talent.” This waste causes damages to the efficacy of production and can prove detrimental if not managed properly.

Reasons:

- Lack of effective communication.

- Conflict of personal interest.

- Poor working conditions.

- Absence of reasonable incentives.

3. System complications:

The procedure of production is lengthy, complicated, and requires a different scale of management at every stage. System complications are a natural occurrence in these types of mechanisms. The lean management names this type of waste as “Excessive Processing.” It can increase production costs and reduce the utility of raw material.

Reasons:

- Lack of interconnectivity.

- Insufficient production units.

- Poor process management.

- Broken or damaged production equipment.

4. Extra Output:

If the production units keep working continuously without rhyme or reason, it results in assembling extra outputs. Lean management uses the term of “overproduction.” These additional units are not above the required demand of the market and therefore go to waste. It results in more costs and fewer returns. Also, overproduction is responsible for wasting useful limited resources.

Reasons:

- Incorrect market survey reports.

- Absence of customer feedback.

- Inaccurate production estimations.

- Mismanagement of resources.

5. Supply Chain deficiency:

From farms to the sales counter, food and beverages cannot travel from one point to another without logistics involvement. If the food in transit is poorly handled, delayed, or subjected to bad conditions, it can have health repercussions. Lean management helps find out the loopholes at various stages of the supply chain and identifies this waste as “Transportation.”

Reason:

- Inadequate packaging of units.

- Misplacement of storage facilities.

- Unsuitable batch sizes.

- Poorly designed transportation vessels.

6. Transit Hurdles:

Time is a resource that cannot be moulded as per our convenience; the smart choice is to plan around it instead. When it comes to the manufacturing process, time is essential every step of the way. If there is a lack of understanding, experience, and management with time, it can result in significant losses and massive amounts of waste. The lean management term for this type of waste is “Motion.”

Reasons:

- Messy operations.

- Lack of expertise.

- Shortage of labour.

- Overused or shared equipment.

7. Poor time management:

Food is cooked, steamed, boiled, mixed, and went through many transformation procedures before making it out of the production line. Even within the factories and manufacturing lines, it requires expert precision, abundant labour, and reasonable costs to shift the food from one production line to another. A problem or delay in this mechanism can cause the loss of entire batches. Lean management deals with the deficiency of products under the banner of “Inventory.”

Reasons:

- Lags in the supply chain system.

- Old and outdated production methods.

- Overused and inefficient machinery.

- Exhausted or poorly regulated labour.

Conclusion:

Lean management identifies every system delay, defect, and interruption as “Waste” in the system. These wastes can be in the form of process, time, labour, and the system’s inaccuracies at any given level. As a result, the manufacturing process suffers, a decrease in profitability, and the efficiency of the system is compromised. It is essential to look at the reasons for these problems to find out better solutions.