Introduction

In a plant or a factory where food is processed in tons every day, there are many large food containers for storage, processing, and cooking the raw material. These gigantic containers are not empty vessels; they have intricate mechanisms and delicate tools attached for monitoring, stirring, brewing, kneading, molding, and transferring food on a massive level. All raw food material is organic, which is perishable. While food is going through different stages during the processing, the small particle can get lodged into corners, nooks and crannies of these containers. To avoid the risk of contamination and upkeep hygienic standards, food containers must be cleaned, sterilized, and disinfected regularly.

Factors For Container Cleaning Procedures

Different factories process different types of food. Some are liquid-based like sauces, drinks, and preservatives, while others are solids, semi-solids, or semi-liquids. Another critical factor is the chemical composition of food; some foods are stickier than others, while others have a high PH or PoH level. When it comes to cleaning up after the processing is complete, some of the most important factors to consider are:

- Acidity: For cleaning the containers, it is essential to understand the chemical composition of the food like acidity, alkaline, or concentration of organic materials. It is crucial to determine what type of detergents can effectively clean the containers.

- Viscosity: Thicker food batches like dough and jams have a higher density and need more potent cleaning methods. Therefore measuring the consistency of the food is necessary.

- Reaction to Temperature: While cooking in oil or steaming in water, food particles change shape and get attached to the containers’ surface layers. These scrapped layers need removing before moving on to the rinsing and sterilizing.

- Reaction to Metal: Certain foods and cleaning chemicals can react with the metal of the food container. It can cause corrosion and damage to the food container. It is crucial to check the chemical composition of food and cleaners before use.

- Polarity: Polar food particles will not mix with non-polar cleaning agents. It is necessary to check the polarity and compatibility of the food particles and cleaners for the best results.

- Rate of Contamination: Some foods can spoil faster than others. It is essential to schedule cleaning operations with correct intervals, to minimize the risk of spoilage.

Stages Of Container Cleaning Procedures

The methods for cleaning a container of dry foods like salted peanuts, almonds, and corn flakes are not useful for wet food containers like soft drinks, jellies, and soy sauce. Every food processing plant plan, execute, and employ different cleaning methods based on cleaning procedures. The most common stages of cleaning processes are:

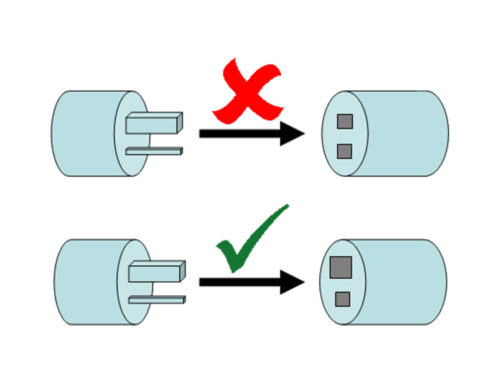

- Unloading: The food containers with liquid or solid foods are not clean without completely emptying it. Many food containers design and engineering helps to drain them out entirely. Some food containers have detachable latches at the bottom, while others can flip upside down. This type of total unloading helps minimize the waste of food as well.

- Rinsing: The processed food is safely transferred into the next processing stage to rinse the empty food containers with water or gases. Stabled, dry, and lesser viscose foods are easy to rinse with water. For thicker, more acidic, and non-polar foods like vegetable oil, gases are more effective.

- Manual Scraping: Some foods may stick and harden on the surface of the food containers while cooking. These layers of residue will remain stuck inside the box even after unloading. Many scraping devices come in handy to flay these stubborn food leftovers. In most cases, workers use a manual scraper to ensure a thoroughly cleaned out container.

- Chemical Washing: Chemical cleaning agents and detergent clean out the smallest food particles in the emptied and scraped out containers. Workers use brushes or automated sprinklers spray and coat the entire vessel with the chemical cleaning agents. After the scrubbing, another water rinse cleans out the detergents.

- Disinfecting: All food materials are perishable and start reacting with bacteria as soon as they contact open air. Therefore, disinfecting and sterilizing is a mandatory cleaning procedure in compliance with health and safety regulations. Some food processing plants also monitor and secure the air inside the factories to avert the contamination risks.

Conclusion:

Food container cleaning procedures are necessary to safeguard the health of the consumers and health code directives of the FDA. These cleaning procedures keep lawsuits away from the manufacturers, build food quality, and save them from legal penalties. Food container cleaning procedure is also essential to regulate the looks, taste, and smell of processed food products.