The process of condensation in a food factory is inevitable. But, if proper procedures are not followed to mitigate the situation, then there are possible chances for food contamination in the case. The condensed water can harbor and transport bacteria on the food.

Hygienic and food safety protocols are compromised due to condensation. Condensation can carry harmful pathogens like listeria and put the whole factory under risk due to which contamination can occur, and the production plant may face shut down. That can result in a big loss.

Hygienic and food safety protocols are compromised due to condensation. Condensation can carry harmful pathogens like listeria and put the whole factory under risk due to which contamination can occur, and the production plant may face shut down. That can result in a big loss.

However, the factory workers make sure to avoid this. Food factories make the use of different techniques to prevent condensation. Below are the points which can be used to prevent condensation in food production zones.

Tips to avoid condensation in food production zones

1) Proper Ventilation

The first and foremost thing to do for reducing condensation is that the area should have balanced ventilation. The main reason for condensation is when humid air enters a cold room through doors. So avoid such conditions food factories must

- Assess and monitor the airflow throughout the production area.

- Try to measure the fluctuations in humidity levels. Check the pipes, ceiling conduits, freezer openings, and cooling units.

- Avoid moisture formation on the walls and ceilings by keeping the airflow balanced in the entire facility. (Usually, unbalanced airflow produces condensation which ruins the food production.)

- Ensure that the airflow from each point of exhaust and supply is stable.

- Properly evaluate and determine the desired airflows between the adjacent spaces.

- Ensure that drip pans and quat chemical blocks are in the proper place.

2) Installation of Dehumidifier

To avoid condensation and moisture,it is recommended to install a dehumidifier. It will be able to eliminate any humidity that enters the area. However, while choosing a dehumidifier, make sure you get the best one. It is recommended to

- Use a desiccant dryer, it lessen the humidity.

- Develop an HVAC system for the food production area.

3) Cover The Food that Produces Moisture

There is a possibility that the food itself is producing condensation, and the moisture is escaping into the air because of natural respiration. For this, food facilities need to control the moisture that is coming from food like fruits and vegetables. For that

- Cover such foods and ingredients, so the condensed water doesn’t affect the air.

- A large volume of water vapor is produced from stoves or ovens. So, Griddles, hot water kettles, or any warm product should also be adequately covered.

- Place the product in a balanced ventilated area immediately after removing it from the hot oven.

4) Clean the Surfaces

Workers need to clean the floor if any water spill happens, immediately. Water can evaporate from the wet surface and will increase the humidity. Spills, Leaky pipes, hoses, conveyor lubrication, and clean up operation leaves water on the floor. So, food facilities should properly monitor and make sure to

- clean spills thoroughly and dry it properly afterward. Don’t let the water stand on the floor. It will escape in the air and produce moisture. (Cleaning equipment should be sanitary, non-scratching, and non-shedding.)

- Clean and sanitize the extension poles as well.

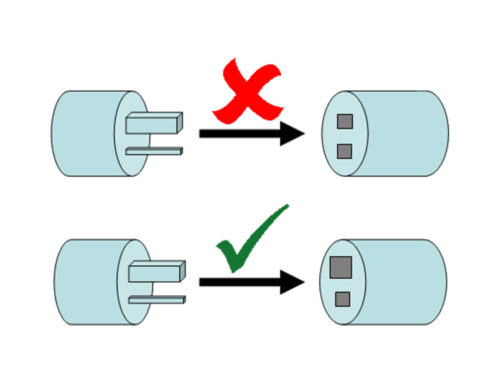

5) Insulate the Pipes

Insulating the coolant pipes is yet another solution to avoid condensation. For that

- Pipes installed near food areas should be insulated adequately or this will allow moisture to form around the facility, and this will increase the risk of contamination. Insulation will prevent unwanted heat loss or gain.

- Cover the pipes using appropriate material.

- Control and direct the condensed water to drains.

Conclusion

Condensation is a critical problem that impacts the food industry. It is often underestimated and due to which the factory owners have to face severe consequences afterward. The food production becomes slow, contamination breaks out, or the quality of the food is not up to standards. It becomes the cause of loss of income and profit.

Furthermore, ask your sanitation service to give you guidance and tips about how to control and prevent condensation. The advice of a professional will undoubtedly help you to make sure your production is of good quality. Make sure to hire a professional and expert service provider who will be able to tackle the condensation issue, and your production plant will be able to run efficiently.