To produce safe and hygienic food, work starts from the farm and factory, concluding when the food reaches the dining table. Ensuring food safety and food hygiene is the primary necessity of food production plants. So, to prevent food contamination in the production area, factories use the concept of hygiene zones. Hygienic zoning is the best way to meet hygiene and sanitation standards for producing healthy food.

Let us have a look at the basics of hygiene zone concept in food production.

What is Hygiene Zone Concept?

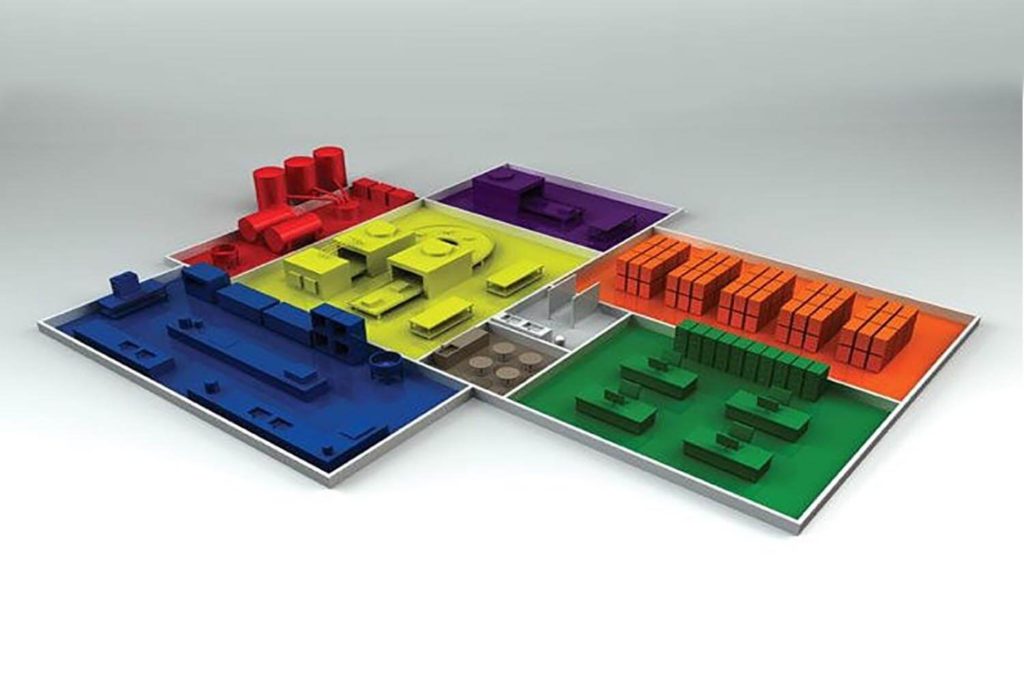

Hygiene zones refer to the division of the food facility areas after conducting hazards analysis and risk assessment by Hazard Analysis Critical Control Points (HACCP). By hazard we mean the probability to cause any damage. The division depends on the probability of food contamination. The occurrence of physical, biological, and chemical hazards results in conceptualizing these divisions.

Hygiene zones refer to the division of the food facility areas after conducting hazards analysis and risk assessment by Hazard Analysis Critical Control Points (HACCP). By hazard we mean the probability to cause any damage. The division depends on the probability of food contamination. The occurrence of physical, biological, and chemical hazards results in conceptualizing these divisions.

One thing to keep in mind is that the zoning depends upon the type of food industry. There is no perfect solution for factory zoning. Different manufacturers opt for different procedures that decides the hygienic zoning. For example, in some food and beverage industries, the sorting and grading of fruit are done in the field or some food facilities do the process inside the factory in the basic hygiene area. Similarly, for Ready to Eat (RTE) foods manufacturers will process canned or preserved RTE food in medium hygiene areas but decontaminated RTE foods in which there is a potential of microbial growth, they processed it in high hygiene areas. By this, we can understand that the level of hygiene depends upon the likelihood of microbial contamination.

Thus, depending on the severity of risk and type of food and beverage food factories divide areas into low risk, medium risk, and high-risk areas. Let us understand what areas or zones of a factory or a plant should be clubbed according to varying risk factors.

Low-risk areas: (Basic Hygiene zone)

Low-risk areas mean where the risk of product contamination is low. These are the areas where a product has the least exposure to the environment. That is why it is a basic hygiene zone. The areas that include low risk are

- Unexposed foods or closed package or cartons

- Finished goods or raw material storage areas that require monitoring, reduction & control on the hazards caused by pests and insects

- Areas where cleaning and sorting raw material is observed

- Waste handling areas.

- Also, it includes protection from any dirt, dust, or other sorts of contaminants from the outside of the premises.

Medium risk areas: (High care zone)

The medium-risk area is the high care zone. This zone includes areas where there is any exposure to food products with the environment. These areas are though important to control but there is no chance of any microbial contamination neither it affects the consumers.

Medium risk areas include

- Raw material receiving areas

- ingredient preparation areas as poultry, the slaughtering, and cleaning area.

- Wet and dry processing areas etc.

The aim here is to mitigate or control the occurrence of any hazard through any potential sources in these areas.

High-risk areas: (High-risk zone)

High-risk area or high-risk zone is a way too sensitive area. There is a high potential for contamination in these areas. These are mostly manufacturing areas where there is any risk of microbial contamination in products that affects the consumer group. These areas include

- Exposed food areas

- Contact of tools and utensils with food

- Food processing zones

- Addition or mixing area of an ingredient while processing etc.

Proper hygiene practices are important to reduce the risk of any microbial contamination in high-risk areas.

Why do we need hygienic zoning?

Hygienic zoning is necessary for food factories to produce healthy, and wholesome food. Hygiene zoning allows food factories to control the risk of product contamination efficiently. Hygiene zoning is needed

- To avoid the risk of product contamination

- To maintain hygiene and sanitation standards throughout the food processing chain.

Conclusively, every food facility must focus on physical separation, process outflow, and training of employees. All this can ensure the proper execution of hygiene zoning. By following good hygiene and qualitative manufacturing in hygiene zones, a food facility can apply standard measures of food production.