Productivity Improvement through 5S

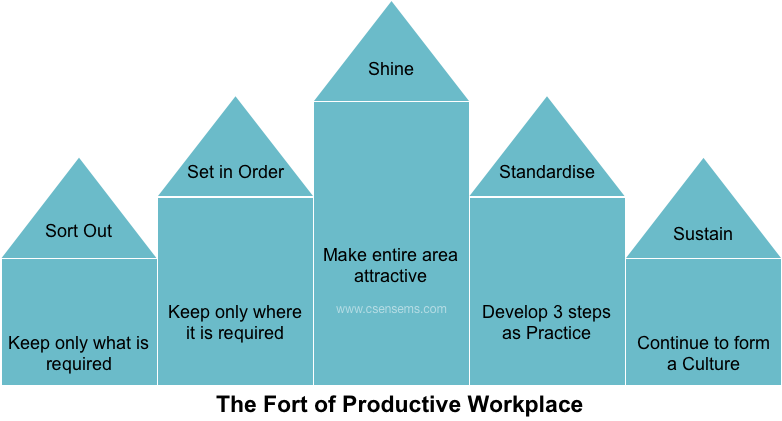

5S training & Workshop is designed to cater the needs of every level of staff in an organisation on keeping the workspace safe, pleasant and productive. It is not all about housekeeping and cleaning. But it is the simplest productivity improvement methodology. It can be successfully implemented by everyone, every day, everywhere – at every size of

It is not all about housekeeping and cleaning. But it is the simplest productivity improvement methodology. It can be successfully implemented by everyone, every day, everywhere – at every size of the organisation, whether it is a manufacturing, tool room, bank counter, restaurant, hospital, medical shop, IT company or be your home.

Introduced by Ford in his Ford Automobile factory, in the US as CANDO – a short form of Clean, Arrange, Neat, Do it Daily and Ongoing Improvement. It got exported to Japanese Industries through industry experts of both Japan and the US and found its prominence in Japanese Manufacturing Industries.

5S is considered to be the secret of Japanese success in continually improving manufacturing plants' productivity, improved safety on the shop floor and enhanced the morale of the employees.

Philosophy

Cleaning for Ownership

A Person who cleans and maintains a property becomes the moral owner of it. By cleaning his workspace or machine, a person becomes attached to it. Cleaning is

Cleaning is inspection

A person comes to know the potential damages, abnormalities at an early stage by cleaning daily. Thus 5S reduces the chances of breakdowns, accidents, and other losses.

Cleaning for Positive Energy

It is not all about cleaning. But it is about remaining positive and attractive. The Objective of 5S is to keep the workspace, machines, and people attractive all the times (step 3 – Shine). Good attracts Good.

Benefits

Improvement in the following areas are seen from day 1 of implementing 5S

- Productivity

- Safety

- Equipment Availability & Utilisation

- Cost reduction

- Space utilisation and saving

- morale of staff

Engineering Services

Civil/Structural/Architectural Engineering

Automation/Instrumentation Engineering

Procurement Services

Enquiry preparation to order placement

Engineering Consulting Services

Food Technical & Regulatory: