Food production is the most challenging type of manufacturing, which requires complete care for hygiene. For any food facility, uniformity is the key. It takes a well-controlled and well-designed operation for good quality food production. Extra safety and cleanliness are crucial for sustaining food safety.

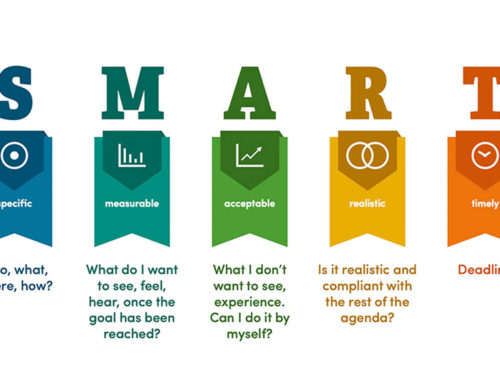

Optimization is a prime decision when drawing a balance between maintaining the quality of food and meeting the demand variable in food industries. It’s essential to optimize the manufacturing process for higher results and also improve efficiency. Here are four effective ways to optimize food production.

Optimization is a prime decision when drawing a balance between maintaining the quality of food and meeting the demand variable in food industries. It’s essential to optimize the manufacturing process for higher results and also improve efficiency. Here are four effective ways to optimize food production.

1) Use of Technology

This is a technology-centric era. Food officials and their managers must use technology in food production.

● Use Forecasting Tools

Forecast tools can be used to find out how many food products should be produced in the future. Food managers must use forecasting methods to forecast future needs according to market needs. By using these methods, food manufacturers avoid unnecessary production and avoid more inventory.

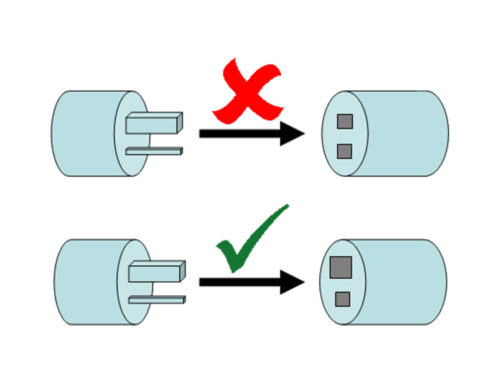

● Use Automation

The use of robotics and Artificial intelligence (AI) in the manufacturing process benefits the production facility. The conversion of manual labor into automatic labor leads to higher food production effectively. And machinery never gets tired unless the physical problem comes; hence the production is fast. For packaging, food officials must use automation techniques for optimum productively.

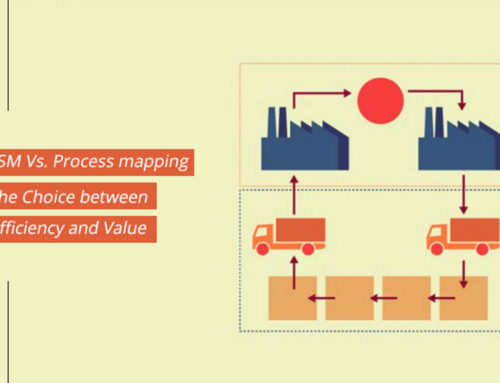

2) Improve Management

To run the production process flexibly, factory managers must check out their inventory every week and improve management to avoid any production process failure. Proper Management food officials know their stock before the end.

- It helps the food managers to manage them according to the need.

- To avoid any delay in production, food managers should use management tools to save time and money.

3) Food Manufacturing and Safety Protocol

Safety and food manufacturing protocols must be implemented by food officials to avoid any mishaps. Safety is the first key for any firm. It’s essential to manufacture food using safety measures. Following safety protocols are necessary. If neglected, then there can be a chance of food contamination. This could lead to the loss of production and the shutdown of the whole production plant. It will drastically decrease the overall venue.

Some of the safety measures are;

- Cleaning and sanitizing

- Maintenance

- Environmental hygiene

- Maintenance hygiene

4) Determine Customer Demand

Customer demand changes rapidly. It needs to be determined who is the targeted audience and what exactly do they want. People prefer eating chicken and eggs mostly, but sometimes, when there is a rise in bird flu, many individuals don’t buy or eat such items. This affects the production factory adversely as the leftover items are sent back to them.

Hence, food officials must keep their eyes on customer needs to create effective products and according to customer needs. It is also wise to take feedback from the customers and ask what they prefer more. Producing the items that will be purchased more will help optimize the selling rates. Waste products will also be in less quantity. This will benefit the entire facility production.

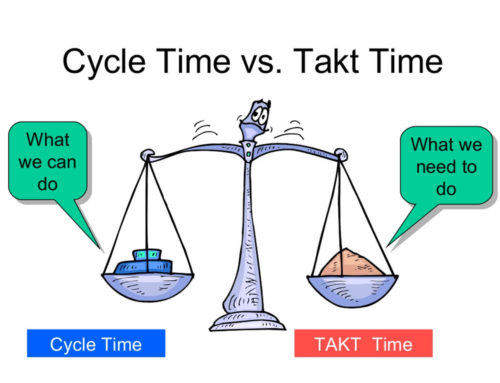

5) Machinery Checkup Schedule

Regular maintenance of all machinery and equipment must be assured. Machinery is a vital part of the entire food production. Therefore, all machines must work in perfect condition 24/7. Machines should be stopped at a specific time and get the necessary maintenance.

- This will ensure that the power-off time doesn’t affect the production rate.

- The machinery performance will be up to the mark.

Conclusion

Optimizing the food production process will help food officials and managers improve many business things, especially their customer satisfaction. Customer satisfaction is vital in any place because if your customer is happy with your product, then the profit will rise.

Managing and optimizing the manufacturing process is indeed a bit complex and challenging. Still, well-trained employees and the use of technology help the food manufacturer to produce a good amount of food products.