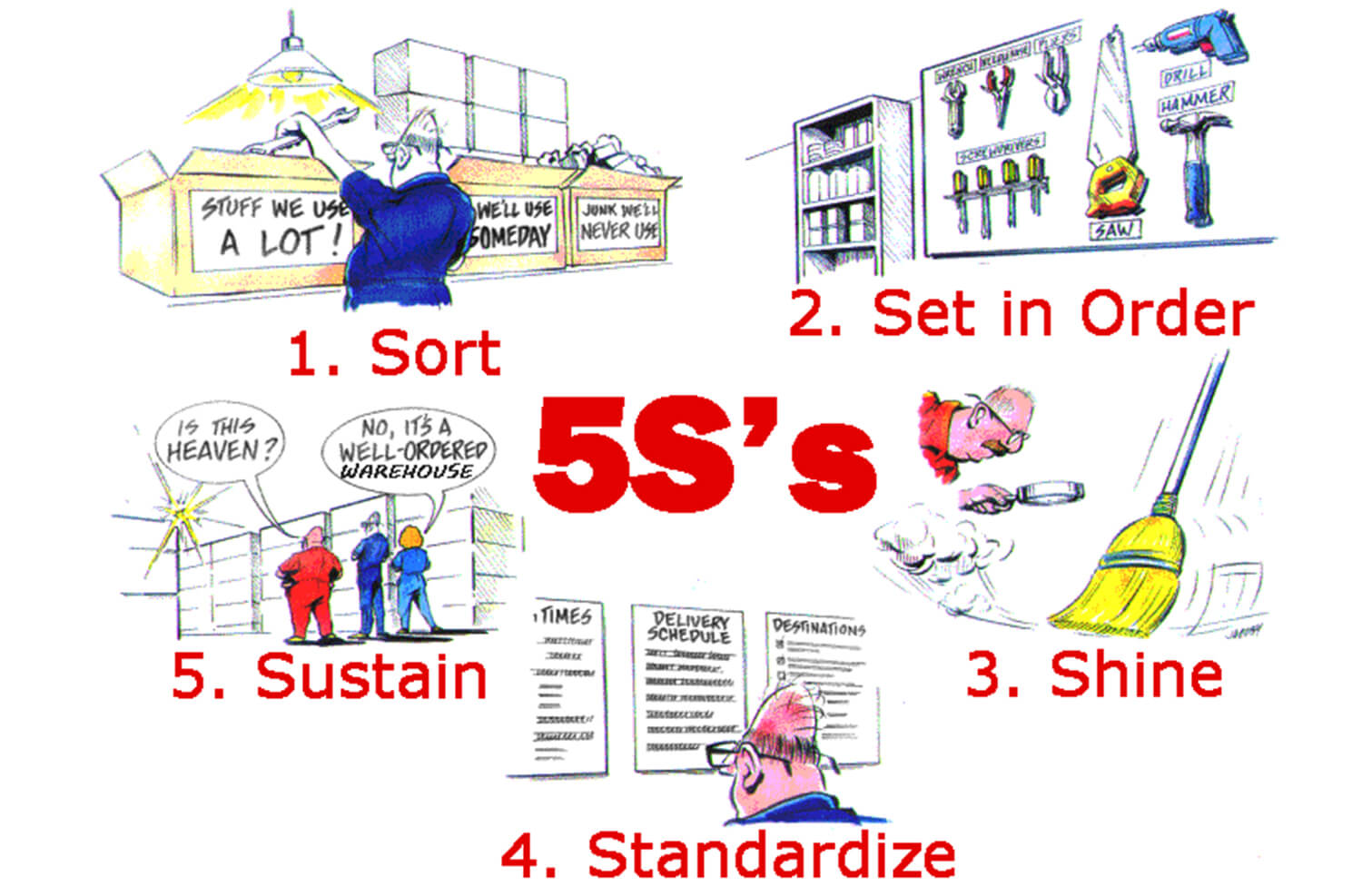

We learned about 5S concept in the previous part. Now, as we step ahead, the point is to implement the 5S in the food industry, let’s explore how an industry can implement 5S?

Implementation of 5S in the Food Industry:

5S is the basic need of all the industries to reduce the work chaos. Let us undertsand how 5S can be implemented in the food industry:

5S is the basic need of all the industries to reduce the work chaos. Let us undertsand how 5S can be implemented in the food industry:

1. Set the Scope:

Whenever it comes to anything related to the food, the first thing that comes into the mind is “hygiene”. It should be made clear that food safety and hygiene practices should be given the topmost priority while implementing 5S techniques. The critical compliance expectations should be aligned to GMPs.

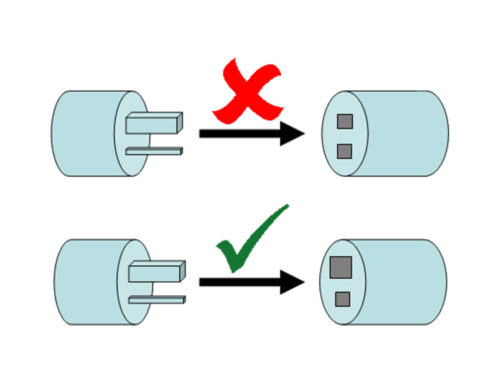

2. Colour-Coded Tools:

Tools used in different hygienic zones can be sorted by colours and easily identified while they are needed. Colour-coded tools can be used with zone planners for easy visual standardization. With the help of such orientation of tools, the food industry can reach the hygiene standards.

3. Hygienically Designed Tools:

5S helps in improving the sanitation and hygiene condition within the workplace. It helps in improving the material handling standards by opting for the hygiene friendly tools and equipment that ensure compliance to the food safety by having the standardized criteria of the assortment, storage, packaging, care, and maintenance of the items.

4. Training and Development of the Employees:

The 5S technique might be shared in the upper management, but it cannot be implemented without the coordination of all the employees working in an organization. It is necessary to educate the employees about 5S and give them the responsibility to explore the methods and opt for the easier ones which they can sustain in the long run while keeping the processes efficient.

5. Assessments of Improvement

5S is to be sustained in the long run, and for that, it is essential to assess the processes. For the evaluation, the food industry should create a review and a tracking system that ensures that all the sanitation processes are kept in track, and the quality and hygiene of the products are kept intact. The assessment can simply be done by training the employees to audit one another and suggest better solutions to avoid quality issues while maintaining food safety.

Benefits Of 5S in the food industry:

There are numerous benefits of implementing 5S out of which few are mentioned below:

1. Ensures Safety:

5S helps in reducing cross-contamination risk, which can be hazardous for food items. Most of the food safety and hygiene issues are because of unhygienic food items and their manufacturing. 5S’s primary motto is to provide everyone with safe food items and make sure that the food manufacturing companies are following hygienic processes, which ultimately helps in resulting fewer cases of food poisoning, an increase of ethical employees, and reduces damages of the workers as well.

2. Improves Efficiency of Workplace

Since the process is well-defined and things are in place, so the employees are always audit-ready if something goes out of order. However, the variability in the operations can be reduced by improving the quality of the procedures. Still, 5S enhances the efficiency of the workplace in the best way. It just not works on hygiene but also increases productivity, which helps the best to return the invested amount on a particular product.

3. Helps in Management:

Colour-coded tools have a longer life because they are placed where they should be and are less prone to damage. Since 5S is a visual process, it helps the employees in suggesting better methods which ultimately results in the ownership of their tools, machines, processes, and thus, the organization. Time to time cleaning is the need of the food industry while production so the tools need to be accessible. If the tools aren’t available to the employees’ proximity, they can get unsafe. It teaches the lesson of self-discipline as well.

4. Helps in Reducing Defects And Errors:

5S helps to improve the productivity of the workplace and work process by reducing the defects and errors. The management of equipment and tools helps to reduce the loss and damaged items because the respective labelling helps in discarding or replacing the defected items in the chosen locations. It also helps in reducing the misplaced items. Also, waste as a result of the inefficient production process is reduced.

Hence, 5S implementation adds value to food industry and excel the operations a great deal.