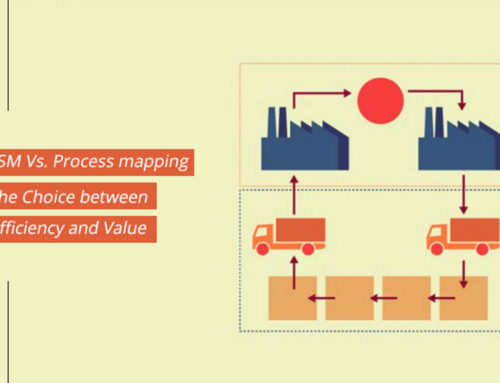

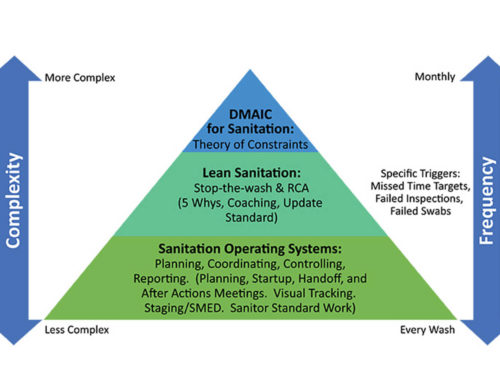

The food factory is a food premise that runs through different manufacturing cells. Along with that, plenty of challenges await the workers and operators to come up with, regarding hygiene and food contamination. To ensure food safety, designers and planners have to play a significant role in designing the equipment and facilities for suitable factories.

Thus, there are some rules and principles that a designer should keep in view, to establish a food factory legally.

Equipment Design

Equipment Design

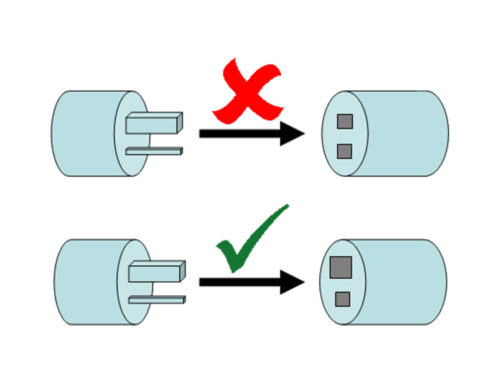

Equipment used for manufacturing food plays a crucial part in food safety. The National Sanitation Foundation has developed a few principles to ensure the prevention of food from contamination.

Furthermore, this foundation has sought recommendations from the health officer and approved them. So, food factories can implement those principles and establish a hygienic and well-designed food factory. Thus, the principles follow as,

- Quality of Equipment must be commercial grade and should be preferably certified.

- If the equipment is not certified, the health officer must approve it according to its usage, for food safety.

Moreover, the equipment should possess the following qualities,

- If it is massive and large that is not movable, it must be mounted on wheels to help it move quickly from one place to another.

- If it is not mounted on wheels and not movable, it must be locked to the floor.

Or

- The designer must mount it on legs, maintaining a height of 15cm (6 inches) from the floor.

- The location of equipment should not prevent any part of it from cleanliness.

- A separate countertop must be set on legs at a minimum distance of 10cm (4 inches) from the piece of equipment.

Thus, these are the basic rules and principles that a designer should consider to prevent any hazardous situation.

Furthermore, the equipment used for food processing must be of exceptional quality, preferably stainless steel. As stainless steel is good in quality, washable, and withstands the harsh chemical cleaners. Moreover, stainless steel is a corrosion-resistant material too.

Types Of Equipment

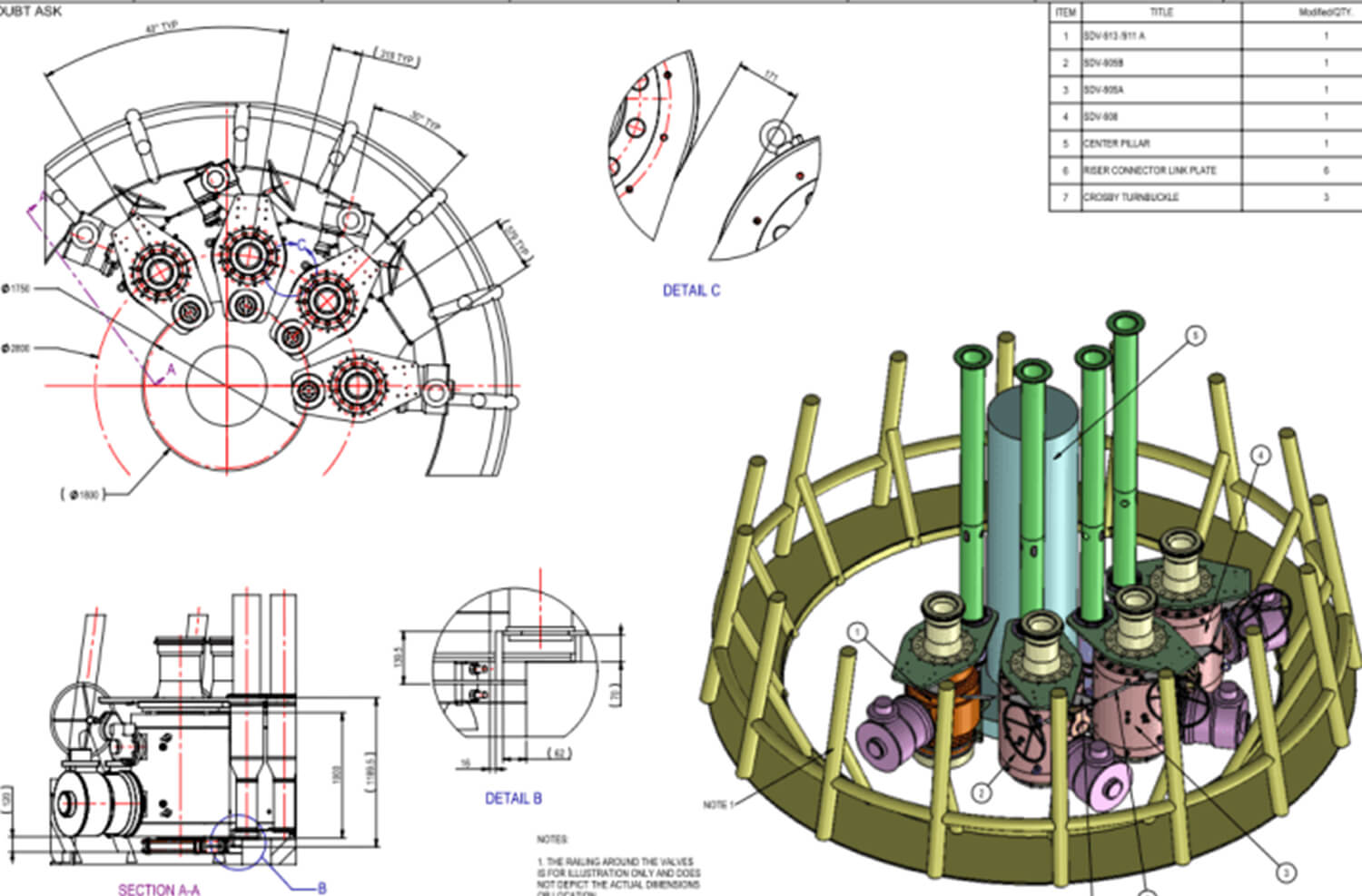

A designer comes through two kinds of equipment that are essential for the food factory.

A designer comes through two kinds of equipment that are essential for the food factory.

- Process equipment

- Mechanical equipment

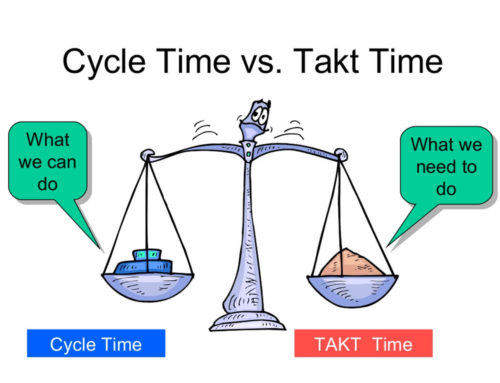

Process equipment is those who perform the task of manufacturing food in the factory. This equipment handles the food, cooks, stores, and packaging the food.

Although all of these equipment work to handle the processing task of solid, semi-solid, and liquid food, selecting the optimal design of equipment depends on the type of tasks that are required to be performed. Thus, a designer must wisely choose the design according to the food that factory manufactures.

Moving to another type, Mechanical equipment is electrical machines that ensure food safety. It relates to water supply, air-conditioning, heating, draining ventilating, and to many more similar purposes.

Installation Of Equipment

The engineer who installs any equipment must discuss the work with the manufacturer before starting it. So, everything works out quickly according to the plan and prevents the growth of health risks. Thus, there are some rules that a technician should follow to avoid any obstacles,

- seek instructions from the manufacturer to work accordingly.

- should ask the manufacturer about electrical requirements and other necessary things for the factory to install equipment like power, pneumatic, and communication cables.

- If relocating any pipeline is necessary, the installer should do it before the installation. Otherwise, it can lead to creating a mess in existing components due to their size and space they occupy.

- should ensure the floor’s thickness regarding the weight of equipment that he has to install.

- If the installation requires any chemical wash during the process, the installer should share the details with the manufacturer.

In installing the equipment, the engineer is an installer while the manufacturer is a supplier. To keep it professional, an installer should ask the manufacturer in written form to avoid any uneasiness afterward.

Conclusion

These principles are not an alien concept for the designers instead, similar to those principles that are for chemical industries. Therefore, every rule and policy reflects the tip to prevent food contamination. Thus, the manufacturer should view all the rules and principles while making a layout for the design and installation of equipment. Moreover, he should supply the installer with all the things required for installation.