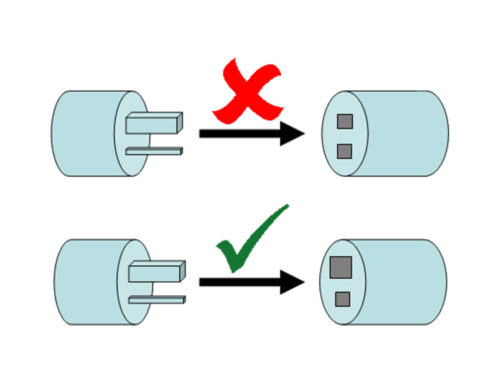

The design of a food factory brings a lot of effect on processed food and its hygiene. The design includes pipework, whether for food manufacturing or drainage and let out the waste. The pipework is an essential part of any food factory because no manager wants to contaminate the food due to bad installation or poorly engineered pipelines.

Therefore, when designers hand over the description of the pipework design to the mechanical engineer, it should be clear and accurate. Consequently, engineers can work on it according to their preferences.

Therefore, when designers hand over the description of the pipework design to the mechanical engineer, it should be clear and accurate. Consequently, engineers can work on it according to their preferences.

Moreover, to design a food factory, manufacturers should find the best engineered and installed pipework. The designer should keep in view a few important aspects when working on the pipework’s. Those aspects comprise the material, layout, drainage locations, and barriers in the layout of pipework.

The Material Of Pipes

The material decides the quality of food that the factory manufactures. If the material of pipes is good enough and washable, it will assist in maintaining the sanitation of the factory.

The pipes that the food factories use vary in material with its diverse qualities.

Some of them are,

- Polypropylene

- Stainless Steel

- Cast Iron

If you are thinking about developing the pipework in your food factory, you should select the appropriate material. To check the material, you can use chemical cleaners and the water’s temperature when you wash the pipes. It will help you decide which works most efficiently for you.

Furthermore, if you are using Polypropylene material for your pipework, then know a few features about the same. It works best when put against the raspy chemical cleaners, but it does not accept high temperatures.

If you are thinking about Stainless Steel, it can be a bit expensive, for your information, but works best against chemical cleaners. Moreover, it fits in both high and low temperatures.

The last material I will discuss is Cast Iron. Although it does not resist chemicals, it keeps up with high temperatures. Thus, it is based on your budget and expenditure planning.

Ventilation In Pipes

The workers and managers of the food factory ensure clean, hygienic food supplies to their clients and customers, along with careful handling the sanitary issues. Thus, venting in pipes is one of the essentials.

Therefore, a designer should ensure the venting in pipes. As it benefits in,

- It is letting the water flow easily through pipes with the help of air that passes by.

- Helping to prevent food from contamination.

- Keeping out sewer gases.

- They are allowing the waste-water and odor to escape.

Layout

The efficient layout is the key to a dependable and good piping system. The designer should select the most well-organized routing along with abasing the number of code-request vents. It can help in the reduction of,

- Labour

- Cost of Material

- Charges of Installation

The pipes should run through the walls, floor, and ceilings in the food processing rooms throughout the food factory building to keep it well-maintained.

Barriers In The Layout

The overall layout of the food factory, its toilet areas, and food processing areas can create difficulties when designing a layout for pipework. These areas add-in for a proper drainage system in the food factory. Therefore, designers should over-view all of the areas of,

- Food processing rooms

- Toilets

- Storage rooms

to create an effective waste-piping system.

Drainage Locations

The architects of the food processor can let you know the proper locations for the drainage system. They will consider all the equipment layout and floor slopes and guidance from the mechanical engineers. Once they figure out the locations, the mechanical engineers can design your waste-pipeworks by considering the size of the pipes. It helped in preventing the food product from getting unhygienic. The designer should be careful about the drainage quality and space because insufficient drainage can cause flooding which can,

- Compromise health

- Put the safety of people in danger at the workplace

- Higher the risk of cross-contamination

Conclusion

The modified and innovative engineers can design the most effective pipework’s for food factories. The description for the pipework should be appropriate according to the food processed in the factory.

Thus, the pipework’s should support installing the food processor and utility system services in the food factory. It should be according to the design of the building. It is keeping in view the nearby places that can create obstacles in supplying hygienic food