From farm to fork, food goes through a lot of processes and equipment in-between. People enjoy fast food and canned foods with confidence after seeing the green stamp by food safety regulations. The biggest concern for food manufacturers is to keep up the clean code.

People don’t get sick from eating food that has travelled thousands of miles to be on your plate. Food sanitation inspectors and food safety authorities must watch the food producers like a hawk. Without food equipment regulations, guidelines, and innovation in the food supply chain, it can become a massive disaster.

People don’t get sick from eating food that has travelled thousands of miles to be on your plate. Food sanitation inspectors and food safety authorities must watch the food producers like a hawk. Without food equipment regulations, guidelines, and innovation in the food supply chain, it can become a massive disaster.

Types of Food Equipment:

Food industry equipment is an umbrella term that covers a wide variety of elements. The most popular classification based on functionality are as follows:

- Processing equipment.

- Storage equipment.

- Transferring equipment.

- Preservation equipment.

- Packaging equipment.

To keep food clean, fresh, and nutritious manufacturers incorporate sanitary protocols in the food equipment designs. These protocols are crucial to remain in business and increase productivity, sales, and profitability. Here are a few sanitation-related tips for food equipment designs:

Food Equipment Design Tips:

It should be clear that authorities work to eliminate three main types of contamination from the food:

- Biological: Bacteria, Pests, and micro-organisms.

- Chemical: Processing chemicals.

- Physical: Dirt particles, sand, hair, etc.

Material and Metallurgy:

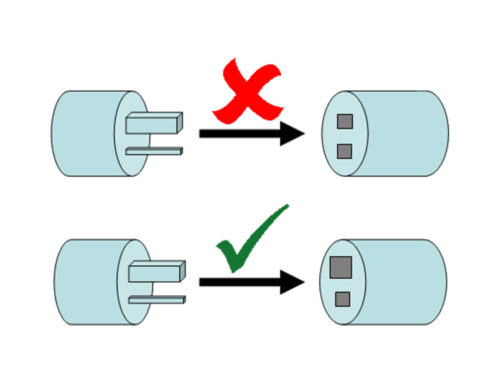

Suppose the food handling equipment is not compatible with the product processing requirements; It may mix, break, or react with the food. To remedy that:

- Certain compounds like stainless steel, polyurethane, and epoxy based equipment are highly regarded.

- Techniques like flash pasteurization should be used for non-metal and non-glass equipment.

- Non-reactive packaging materials (Anti–BPA, nitrates, and phthalates) are recommended for the packing.

The Curing Curves:

It is an acknowledged fact that eliminating perpendicular designs increases the probability of hygiene standards. Smallest of food particles can be lodged into a sharp corner, making it a breeding ground for harmful micro-organisms. All angles, joints, transfer pipes, filling tanks, storage vessels, and other attachment points are molded and curved for smooth and sanitary food equipment.

Welded surfaces are preferred over drilled holes and tapped on lids. Furthermore, other methods like T-joint, lap-joint, or square-butt joint are less effective than the V-shape welding method. All of these measures are to ward-off unwanted cavities for food.

Capacity and Measurements:

A bad design can be an influential factor in compromising food health standards. It is essential to choose the right capacity and structure. Hare a few tips for that:

- A structure that does not let the food particles get stuck in the corners and crevices.

- A construction to ensure that the food equipment is free from holes or small parts in direct contact with the food.

- Setup minimal flat-surfaces to discourage micro-organism growth.

- Design to allow complete and easy access to an entire batch of food.

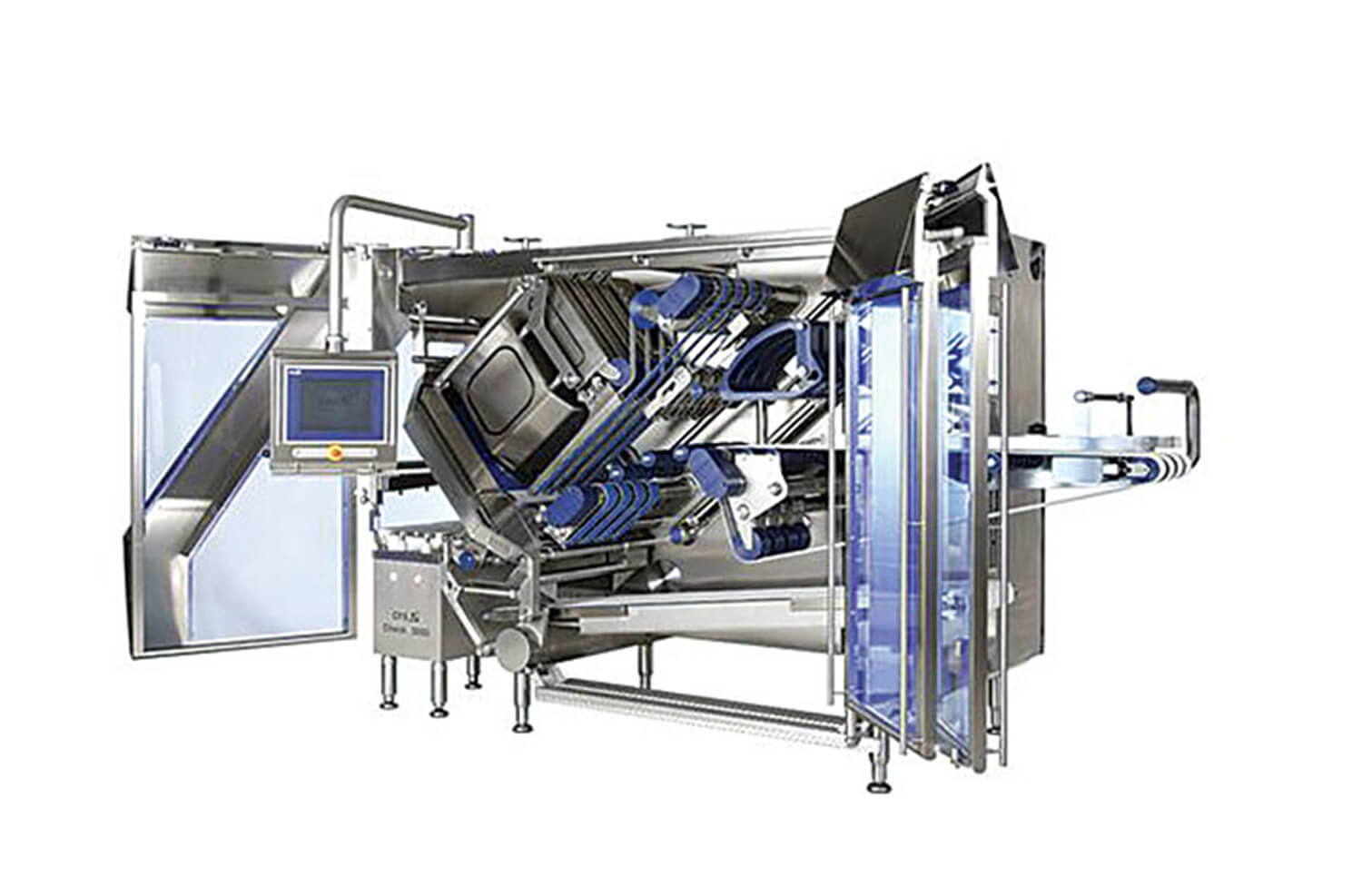

Cleaning in Place (CIPs):

Old and heavy food equipment is challenging to remove, clean, and replace. A CIP is an add-on unit to integrate with the food facilities without taking them apart. Here are some of its benefits:

- It attaches to the food equipment and performs secondary sanitation protocols.

- It helps in the systematic and thorough cleaning of the food equipment.

- It saves time, energy, and costs of the food sanitation process.

The Standing Points:

Too many feet imply too many sources of pest invasion and contamination of food. The best way to deal with this problem is to incorporate as little peddles and foot stands in a piece of food equipment as possible.

The housekeeping:

Human workers are involved with handling and supervising the food equipment. The risk of physical contamination like hair or nails is always present; therefore, manufactures must heed the following tips:

- Use of regularly sanitized clothing like plaid shirts, aprons, over-alls, and pull-overs.

- Implement strict application and monitoring of sanitization protocols.

- Ensure ample supply and active use of hair-nets, gloves, and rubber shoes.

- Avoid direct or bare skin contact with the equipment as much as possible.

Conclusion:

Without the presence of equipment, the concept of food processing is unimaginable. If a manufacturer fails to ensure food safety, it would have a direct harmful impact on their profit margins and sales. There are many types of food equipment involved at every food processing level, like storage, packaging, preparation, and preservation.

Without the presence of equipment, the concept of food processing is unimaginable. If a manufacturer fails to ensure food safety, it would have a direct harmful impact on their profit margins and sales. There are many types of food equipment involved at every food processing level, like storage, packaging, preparation, and preservation.

Food equipment should be proofed against biological, chemical, and physical types of contamination. Design, material, water level, structure, pH levels, and employee screening are the areas where most of the safety regulations are implemented. All these tips and suggestions are necessary to ensure that the final product is safe to use in all kinds of manufacturing processes.